The Optimal Material for Coffee Packaging

- Categories:Industry News

- Author:Jake

- Origin:

- Time of issue:2021-10-12 11:49

- Views:

(Summary description)In this article, you will learn what is the optimal material for coffee packaging, and how XWPAK choose the right material for our clients.

The Optimal Material for Coffee Packaging

(Summary description)In this article, you will learn what is the optimal material for coffee packaging, and how XWPAK choose the right material for our clients.

- Categories:Industry News

- Author:Jake

- Origin:

- Time of issue:2021-10-12 11:49

- Views:

Like other packagings, coffee packaging must attract consumers to buy it. Also, coffee bags have specific requirements to keep their contents fresh. This study by XWPAK attempted to determine the optimal material for coffee packaging based on the abrasion resistance of the ink for printed graphics and content freshness.

How did we do the study?

The materials that were chosen to compare were Aluminum (Al), low density polyethylene (LDPE,) polyethylene terephthalate (PET,) polyvinyl chloride (PVC), nylon, and polystyrene (PS.) To determine which material was best for the ink abrasion resistance, ink rub tests were performed. Furthermore, oxygen transmission rates (OTR) were gathered to determine which material would best prevent oxygen from entering the package so that the coffee stays fresh for longer.

Our conclusion -- PET was found to best optimize ink abrasion resistance and content freshness.

After testing, PET was found to be the best optimize ink abrasion resistance and content freshness. This study provides specific material information to describe the potential of using a type of coffee packaging material instead of a multilaminate material. However, more research is needed to see how the use of a material instead of the multilaminates would benefit manufacturers.

Another aspect to consider when calculating CO2 emission is whether the coffee is ground or whether it is preserved as a whole bean when packaged. When the bean is ground, about half of the CO2 is released (vacuum bagged coffee packaging). Therefore, whole roasted coffee beans have a greater need for ventilation than ground beans.

Coffee Printing Package Graphics for the Consumer

Even after achieving high quality coffee in low OTR packaging material, one must also make sure the substrate is printable for graphics that appeal to the consumer. The bottom line is whether or not the consumer buys the product.

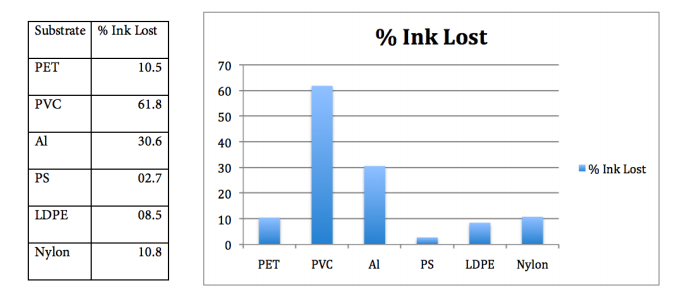

Ink Rub Testing

The ink rub test was performed in the ink and substrates lab on the ink rub tester at the XWPAK lab in Shanghai. The test was conducted face to face using the 4 pound block. The machine rubbed this block back and forth over the same type of material for 100 strokes. It was observed that certain materials had more ink loss than others after rubbing tests. For the purpose of this study, density readings were chosen as a means of comparison between materials for ink abrasion resistance. To do this, three ink density readings were taken before and after each rub test. Three readings were taken at different locations on the materials to account for possible ink placement differences between the flexographic hand-held tester materials. Density readings before rubbing tests are shown in the following table:

| Density Before1 | Density Before2 | Density Before3 | |

| PET | 1.59 | 1.68 | 1.61 |

| PVC | 0.8 | 0.81 | 1.56 |

| AI | 0.45 | 0.97 | 1 |

| PS | 1.58 | 1.62 | 1.57 |

| LDPE | 1.72 | 1.72 | 1.63 |

| Nylon | 1.55 | 1.52 | 1.47 |

Three density readings were also taken after the rub tests were performed and are provided below:

| Density After1 | Density After2 | Density After3 | |

| PET | 1.27 | 1.52 | 1.58 |

| PVC | 0.28 | 0.47 | 0.46 |

| AI | 0.49 | 0.53 | 0.66 |

| PS | 1.59 | 1.56 | 1.49 |

| LDPE | 1.56 | 1.55 | 1.53 |

| Nylon | 1.45 | 1.21 | 1.39 |

These readings were averaged and then divided by the average densities that were taken prior to the rub test. This number was then subtracted from one to determine the percentage of ink lost for each material. The results are shown below. It should be noted that lower numbers are better than higher numbers here because higher numbers represent more ink loss.

As can be seen, the material that lost the most ink by abrasion was PVC (also confirmed by the naked eye) and the material that lost the least amount of ink was PS.

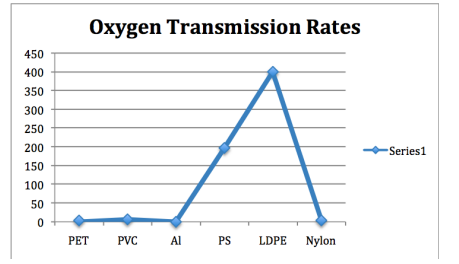

Oxygen Transmission Rates

The freshness of the coffee is just as important as the graphics outside the coffee package. The published oxygen transmission rates of the materials were used to determine which film would be best for coffee packaging. This study uses the oxygen transmission rates of the materials to determine which substrate will work best to optimize the freshness of the content and the abrasion resistance of the ink. This study defines the oxygen transmission rate (OTR) as the amount of O2 that can pass under pressure through a certain amount of area and time.

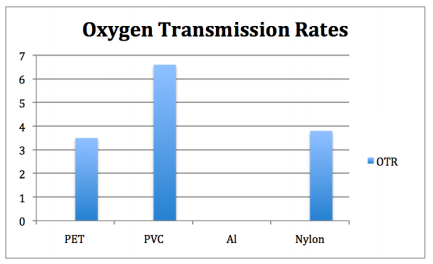

This graph shows oxygen transmission rates in units of cc x thousand / m2 x day x atm, with atm being an amount of pressure equal to 101.325 Pa. Lower OTR numbers mean that the material lets in less O2. Given this information, it can be seen that PS and LDPE cannot compete with the other inferior materials when it comes to protecting coffee from O2 damage. Therefore a more detailed chart is provided comparing PET, PVC, AL and Nylon and excludes PS and LDPE:

High-performance material that optimizes content freshness and ink abrasion resistance

After collecting the above data, the materials were compared to see which was the best material to optimize content freshness and ink abrasion resistance. The study found that PET was the optimal option. This included both the OTR and the percentage of ink lost, as shown in the following table:

| OTR | % INK LOST | |

| PET | 3.5 | 10.5 |

| PVC | 6.6 | 61.8 |

| AI | 0 | 30.6 |

| PS | 197 | 2.7 |

| LDPE | 400 | 8.5 |

| Nylon | 3.8 | 10.8 |

Conclusions:

Although PS and LDPE had low amounts of ink loss in rub tests, the OTRs of the material are too high to be considered for the purpose of this study. Similarly, although the OTR of PVC appears competitive with nylon and PET, its ink loss in rub tests is too high to compare with the OTR of PET and nylon. Since the lower bars mean a lower OTR and less ink loss, it can be seen that the two materials that were compared the most were nylon and PET.

PET drops lower than Ink Loss and OTR Nylon; therefore, PET was determined to be the material that best optimized the freshness of the content and the abrasion resistance of the ink.

XWPAK™ LTD has been a leading manufacturer of flexiple packaging bags in Shanghai for over 10 years. We offer a full line of packaing for different market segment, such as zipper bags, flat bottom bags, stand up bags, paper bags etc.

With a good reputation and years of manufacturing experience, we have succsussfully been working with some great brands in different areas, such as PEETS, Ethical Beans, Costa, etc.

Considering many consumers are now looking for new ways to reduce their impact on the planet and exercise more sustainable choices with their money, and also to protect our montherland, we have developed sustainable packaging solution for your coffee packaging, which is recyclable and compostable.

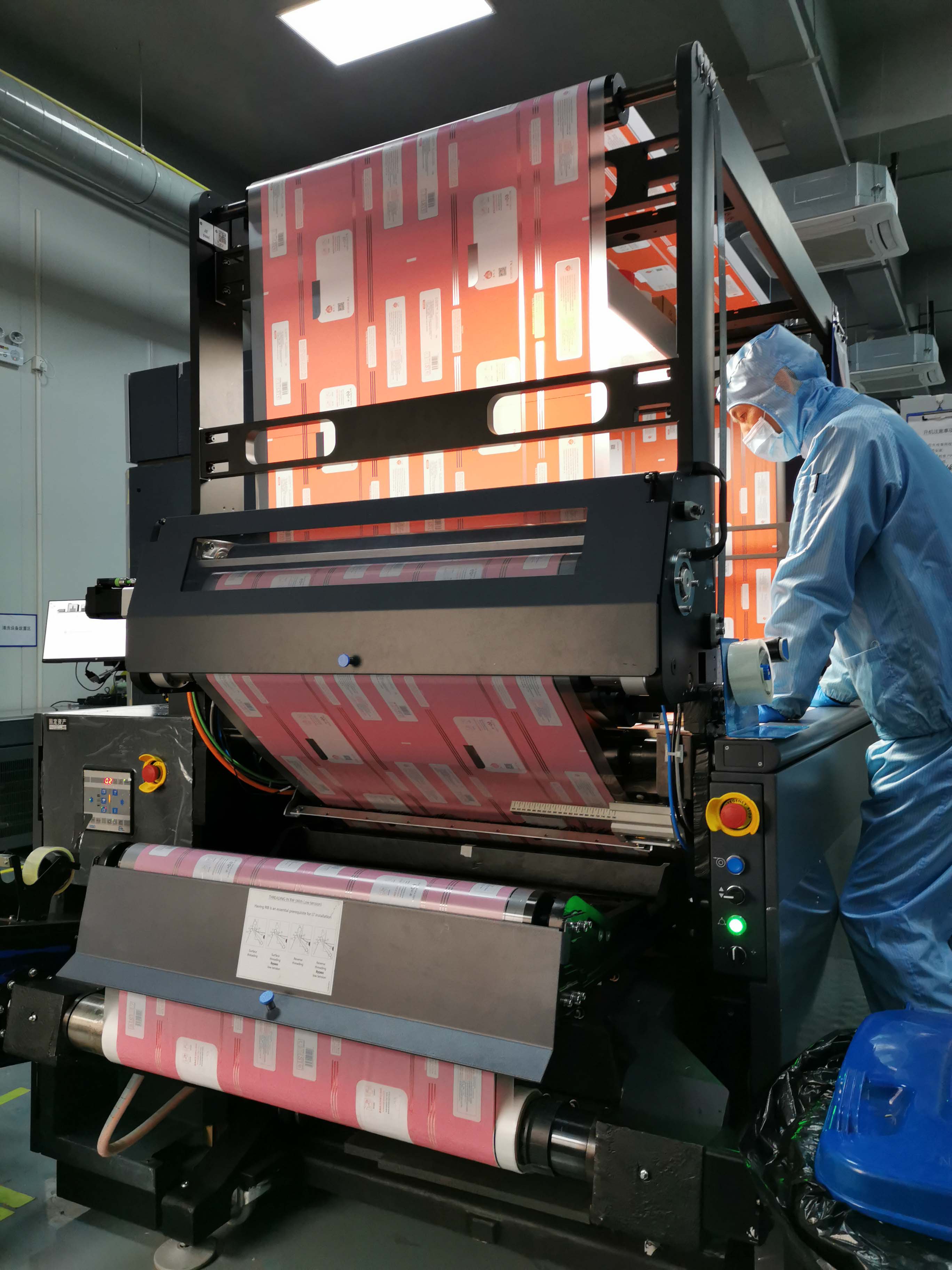

Also to solve the headache of Big MOQ, which is a nightmare for small business, we have lauchned a digital printer which can save the plate cost, meanwhile reducing the MOQ to 1000. Small business is always a big deal for us.

Look forward to cathing up and start the communication.